DIRTY WATER PUMP WQCD, WQD

According to the classification, sewage pumps can be divided into: submerged sewage pump, pipeline sewage pump, submersible sewage pump, vertical sewage pump, corrosion-resistant sewage pump, acid resistant sewage pump and self-priming sewage pump. Sewage pump models include PW sewage pump and PWL sewage pump. The common water pressure chamber used by PW sewage pump is volute. Radial guide vane or runner guide vane are mostly used in built-in submersible pump. PWL sewage pump impeller and water pressure chamber are the two core components of sewage pump. The advantages and disadvantages of its performance represent the advantages and disadvantages of pump performance. With the progress of society, the continuous improvement of people's living standards and the strengthening of environmental protection awareness, sewage pump has been familiar by people, and the scope of application has become wider and wider. Of course, the sewage pump is only an application name. In fact, the application of rubber lined slurry pump as a horizontal sewage pump is very good. In the treatment of industrial sewage, rubber lined pumps are widely used because the sewage contains acidic or alkaline substances. According to some application cases in the pump industry, the use of rubber sheath and metal impeller in rubber lined pump can not only achieve the high pressure and efficiency of metal pump, but also give full play to the corrosion resistance of rubber material. When treating urban sewage, a filter screen is usually added in front of the sewage treatment tank to block the filament winding in front of the suction port of the pump, so that it can not enter the pump chamber, so that the pump can work better and have a longer service life. Features: 1. Advanced technology is adopted, with strong sewage discharge capacity, no blockage, and can effectively pass through the diameter φ 30- φ 80 mm solid particles. 2. The tearing mechanism can tear, cut off and discharge the fibrous material smoothly without adding a filter screen on the pump. 3. The design is reasonable, the supporting motor power is small, and the energy saving effect is remarkable. 4. The mechanical seal with very new materials can make the pump run safely and continuously for more than 8000 hours. 5. The utility model has the advantages of compact structure, convenient movement and simple installation, which can reduce the project cost without building a pump house. 6. It can be used in the full head range to ensure that the motor will not be overloaded. 7. The floating ball day can automatically control the start and stop of the pump according to the required water level change without special care. 8. The double guide rail automatic installation system brings great convenience to installation and maintenance, and people do not have to go in and out of the sewage pit for this purpose. 9. It is equipped with automatic protection control box to effectively protect the leakage, water leakage and overload of the product, so as to improve the safety and reliability of the product. Advantages: (1) compact structure and small floor area. Because the pump works underwater, it can be directly installed in the sewage tank without building a special pump room to install the pump and motor, saving a lot of land and infrastructure costs( 2) Easy installation and maintenance. Small submersible sewage pumps can be installed freely. Large sewage pumps are generally equipped with automatic coupling devices, which can be installed automatically. Installation and maintenance are quite convenient( 3) Long continuous operation time. Due to the coaxial pump and motor, short shaft and light weight of rotating parts, the load (radial) borne by the bearing of submersible sewage pump is relatively small and its service life is much longer than that of ordinary pump( 4) Low vibration and noise, low motor temperature rise and no pollution to the environment.

3. Generally, the water temperature shall not be higher than 20 ℃

4. Water quality requirements:

(1) Sand content in water shall not be greater than 0.01% (weight ratio); (2) the pH value is in the range of 6.5 ~ 8.5; (3) chloride ion content shall not be greater than 400 mg / L. 5. The well shall be positive, the well wall shall be smooth, and there shall be no staggered well tubes.

5、 Structure description of deep well pump:

The copyright belongs to the author. For commercial reprint, please contact the author for authorization, and for non-commercial reprint, please indicate the source.

WQCD

WQD

WORKING CONDITION

WQD series pum with open runner impeller,which is specially designed,has super-strong capacity.so,the pump not only to be blocked because of sucking in solid particle and fiber impurity,but also avoid easily spoing because of sucking-inabrasive grain.especially used to sewage imigation,construction site,coal,mine,metallurgy,dying and textle industry,etc.water pump with float ball is an automatic controltype,after water level decines to below submersed surface,float ball will automatically sink,then the pump will stop work,after water level increase,float ball will increase automatically then the pump begins running.this protective function prevents motor damage due to dry running of the pump.it saves and needs to tender,very convenient and reasonable for usage

MOTOR

Degree of protection:IP68

Insulation class: F

Continuous operation

With thermal protection.

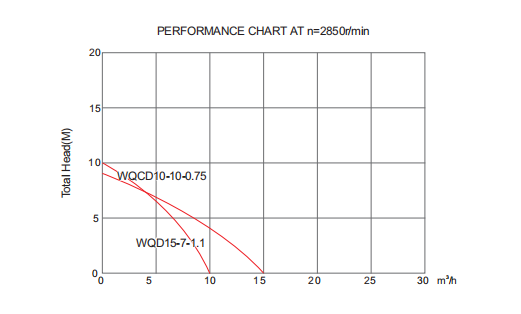

PERFORMANCE CHART

TECHNICAL DATA

|

Model |

Power |

Max.head (m) |

Max.flow (m3/h) |

Max.depth (m) |

Outlet (mm) |

|

|

(Kw) |

(Hp) |

|||||

|

WQCD10-10-0.75 |

0.75 |

1.0 |

10 |

10 |

5 |

50 |

|

WQD15-7-1.1 |

1.1 |

1.5 |

8 |

15 |

5 |

50 |