SUBMERSIBLE PUMP

QJ deep well submersible pump product overview QJ deep well submersible pump is composed of QJ submersible pump and submersible motor. The utility model has the advantages of simple structure, small volume, light weight, convenient installation and maintenance, safe, reliable operation, high efficiency and energy saving. It is suitable for groundwater from deep wells, rivers, reservoirs, canals and other water lifting projects. It is mainly used for farmland irrigation and water for people and livestock in Plateau and mountainous areas. It can also be used for water supply and drainage in cities, factories, railways, mines and construction sites. 2、 QJ deep well submersible pump product features 1. Motor and water pump are integrated, running in water, safe and reliable. 2. There are no special requirements for well pipe and lifting pipe (i.e. steel pipe well, ash pipe well, earth well, etc; Under the permission of pressure, steel pipe, rubber pipe and plastic pipe can be used as lifting pipe. 3. The installation, use and maintenance are convenient and simple, the floor area is small, and there is no need to build a pump room. 4. Simple structure and saving raw materials. 5. Whether the service conditions of submersible pump are appropriate and properly managed is directly related to the service life. 3、 QJ deep well submersible pump structure description 1. QJ deep well submersible pump consists of four parts: water pump, submersible motor (including cable), water pipe and control switch. The submersible pump is a single suction multistage vertical centrifugal pump: the submersible motor is a closed water filled wet, vertical three-phase cage asynchronous motor, and the motor and the water pump are directly connected through claw or single barrel coupling; Equipped with three core cables of different specifications; The starting equipment is air switches and self coupling pressure reducing starters with different capacity levels. The water delivery pipe is made of steel pipes with different diameters and connected with flanges. The high lift electric pump is controlled by gate valve. 2. A rubber bearing is installed in the guide shell of each stage of submersible pump; The impeller is fixed on the pump shaft with a conical sleeve; The guide housing is integrated with threads or bolts. 3. A check valve is installed on the upper part of the high lift submersible pump to avoid unit damage caused by shutdown water sag. 4. The upper part of the submersible motor shaft is equipped with a labyrinth sand preventer and two reverse assembled skeleton oil seals to prevent quicksand from entering the motor. 5. The submersible motor adopts water lubricated bearing, and the lower part is equipped with rubber pressure regulating film and pressure regulating spring to form a pressure regulating chamber to regulate the pressure change caused by temperature; The motor winding adopts polyethylene insulation, nylon sheath durable consumer goods, water and electricity magnetic wire. The cable connection method is according to the QJ cable joint process. Remove the joint insulation, scrape the paint layer, connect them respectively, weld firmly, and wrap one layer of raw rubber. Then wrap 2 ~ 3 layers of waterproof adhesive tape, wrap 2 ~ 3 layers of waterproof adhesive tape on the outside or wrap a layer of rubber belt (bicycle inner belt) with water glue to prevent water seepage. 6. The motor is sealed with precision stop bolts, and the cable outlet is sealed with rubber gasket. 7. The upper end of the motor has a water injection hole, a vent hole and a drain hole at the lower part. 8. The lower part of the motor is equipped with upper and lower thrust bearings. There are grooves on the thrust bearing for cooling. The stainless steel thrust disc is worn against it, which changes with the upper and lower axial force of the water pump

WORKING CONDITION

For clear water. PH: 6.5-8.5.

Solid impurity no more than 0.1%.

Fluid temperature: 0-40℃.

Maximum ambient temperature: +40℃.

MOTOR

Degree of protection: IP68

Insulation class: F

Continuous operation

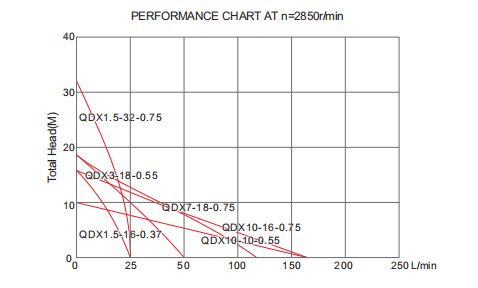

PERFORMANCE CHART

TECHNICAL DATA

|

Model |

Power |

Max.head (m) |

Max.flow (m3/H) |

Max.depth (m) |

Outlet (mm) |

|

|

(Kw) |

(Hp) |

|||||

|

QDX1.5-16-0.37 |

0.37 |

0.5 |

16 |

1.5 |

5 |

25 |

|

QDX3-18-0.55 |

0.55 |

0.75 |

18 |

3.0 |

5 |

25 |

|

QDX10-10-0.55 |

0.55 |

0.75 |

10 |

10 |

5 |

50 |

|

QDX1.5-32-0.75 |

0.75 |

1.0 |

32 |

1.5 |

5 |

25 |

|

QDX7-18-0.75 |

0.75 |

1.0 |

18 |

7 |

5 |

32 |

|

QDX10-16-0.75 |

0.75 |

1.0 |

16 |

10 |

5 |

50 |