VIBRATION PUMP VMP60-1/VMP70

Many processes in industry need to transport fluid from one location to another, playing an important role. It covers a wide range of industries, from large nuclear power plants and ordinary power plants, oil pipelines, petrochemical plants, municipal wastewater treatment plants and water plants, to large and small buildings, ships and offshore oil platforms. Generally speaking, pump is a kind of solid and reliable equipment in rotating machinery. However, in many processes, the pump is a key equipment. Once it fails and goes down, the consequences are often serious or even catastrophic. In addition to direct economic losses, safety problems should not be underestimated or even exceed economic losses. For example, the leakage of radioactive substances or toxic liquids caused by pump failure will affect the lives of relevant personnel of the plant, even the surrounding people. In addition, environmental protection factors are the same. The failure of harmful fluid due to pump leakage will seriously pollute air, water and soil, and even lead to irreversible harm to the environment. The treatment is time-consuming, laborious and expensive. Therefore, although the pump is often not classified as a key unit, it is not too much to pay attention to it as a key unit.

If the pressure in the pump is lower than the vaporization pressure of the fluid (assuming little temperature change), or

When the temperature of the fluid rises to its vaporization temperature, cavitation may occur, and most of the steam

The reason is the former. For liquids with high density, such as water, the harm caused by bubble explosion is higher than that of low-density liquids, such as hydrocarbons. In addition, cavitation occurs for liquids with large liquid vapor volume difference

The harm is also greater.

The damage of cavitation is related to the material, design and operation state of the impeller. Of course, it is directly related to the amount of cavitation. The consequences are shown in the following aspects:

The pressure head of the pump is reduced by 3%, which can be considered as cavitation, but it does not mean that the pump must be damaged.

Noise – burst noise, but not necessarily loud.

Vibration – in a wide frequency range, the vibration amplitude is large, and the spectrum noise base increases. Visually – corrosion is seen on the low-pressure side of the blade, which may be the feature of cavitation. High frequency impact and high temperature corrosion cause pits on the blade surface, which can be spongy and quickly damaged in serious cases.

VMP60-1

VMP70

WORKING CONDITION

For clear water. PH: 6.5-8.5.

Solid impurity no more than 0.1%.

Fluid temperature: 0-40℃.

Maximum ambient temperature: +40℃.

MOTOR

Degree of protection: IPX8

Insulation class: F

Continuous operation

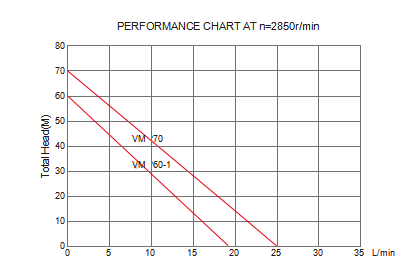

PERFORMANCE CHART

TECHNICAL DATA

|

Model |

Power (w) |

Max.head (m) |

Max.flow (L/min) |

Max. Depth (m) |

Outlet |

Packing dimension (mm) |

|

VMP60-1 |

280 |

60 |

18 |

5 |

1/2" |

295x115x155 |

|

VMP70 |

370 |

70 |

25 |

5 |

1/2" |

320x120x155 |