3.5SDM DEEP WELL PUMP

[QJ submersible pump (deep well pump)] instructions for use:

1、 The motor must be filled with clean water before use, and the water injection and deflation bolts must be tightened, otherwise it is not allowed to use. 2、 The land commissioning shall not exceed one second. 3、 The electric pump is not allowed to be used upside down or tilted.

4、 The motor must completely submerge into the water, but the submergence depth shall not be greater than 70m. 5、 Lead and cable joints shall be operated as specified.

6、 For ordering high lift submersible pump, please refer to the type spectrum of high lift submersible pump and the operation manual of high lift submersible pump【 QJ submersible pump (deep well pump)] installation, start-up and shutdown:

1. Inspection and preparation before installation:

(1) Check whether the water well meets the service conditions of the pump, i.e. well diameter, vertical and well wall quality, static water level, dynamic water level, water inflow and water quality conditions. If it does not meet the service conditions

Corresponding measures must be taken under the conditions, otherwise the pump cannot be put into the well.

(2) Check whether the power supply equipment and power supply line can ensure the normal operation of the electric pump( 3) Whether the power supply voltage and frequency meet the service conditions.

(4) Check whether the parts are safe according to the packing unit, and be familiar with the installation and operation instructions( 5) Check the electrical circuit. The control and protection devices are reasonable, safe and reliable.

(6) Various installation tools shall be equipped, and the vertical tripod and lifting chain (or other lifting tools) shall be safe, reliable and easy to use.

2. Installation

(1) Remove the water filter screen from the machine and pump as a whole, and then open the bolts of water injection and air vent holes to fill the machine with clean water. Be sure to fill it to prevent false filling. And check whether all parts of the motor are

Stagnant water leakage. In case of water leakage, adjust the rubber pad and tighten the bolts according to the components.

(2) Carefully check whether the cables and joints are bruised or damaged, and wrap them in time in case of problems( 3) . the insulation resistance measured with a 500 volt megohmmeter shall not be less than 5 megohm.

(4) Install the protection switch and starting equipment, and check whether the water in the motor is full, then tighten the bolts of water injection and vent holes, and fill water from the top of the valve body until it flows out from the water inlet joint

Start the motor instantaneously (no more than 1 second) to see whether the rotation direction of the electric pump is the same as that of the steering mark. If it is opposite, replace the power connector, and then install the wire guard and water filter net to prepare for installation and going down the well.

(5) Install a short water transmission pipe at the water outlet of the pump, and lift it into the well with a splint, so that the splint is located on the well platform.

(6) Another section of water transmission pipe is clamped with a pair of splints, and then lifted and lowered to connect with the flange of the short water transmission pipe. Lift the lifting chain and remove the first pair of splints to lower the pump pipe and seat it in the well

Fall on the well platform, repeatedly install and go down the well until all are installed, and the last section of splint is not unloaded to fix the pump on the wellhead.

(7) Finally, put on the well cover, bend, gate valve, outlet pipe, etc.

(8) A rubber pad shall be added when connecting the flange each time. After alignment, the fastening screws shall be tightened at the same time in the diagonal direction to prevent skew and water leakage.

(9) . the cable shall be fixed in the groove on the flange of the water transmission pipe, and each section shall be fixed with binding rope. Be careful when going down the well. The cable shall not be used as a lifting rope, let alone hurt the cable( 10) The pump is stuck in the process of unloading. Try to overcome the sticking point. Do not forcibly unload the pump to avoid jamming( 11) When installing pumps in large wells, personnel are strictly prohibited from going down the well.

(12) The, protection switches and starting equipment shall be equipped with voltmeters, ammeters and indicator lights, and shall be installed on the distribution board and placed in a suitable position around the well pad.

3. Start

(1) Measure the winding resistance of the motor with a 500 volt megohmmeter, and the insulation resistance to ground shall not be less than 5 megohm.

(2) Check whether the three-phase power supply line and voltage meet the regulations. All instruments, protection equipment and wiring are correct before closing and starting.

(3) After starting, observe whether the current and voltage meet the specified range, and whether there is abnormal operation sound and vibration. If it is abnormal, find out the cause and solve it in time.

APPLICATIONS

OPERATING CONDITIONS

MOTOR AND PUMP

OPTIONS ON REQUEST

WARRANTY : 2 YEARS

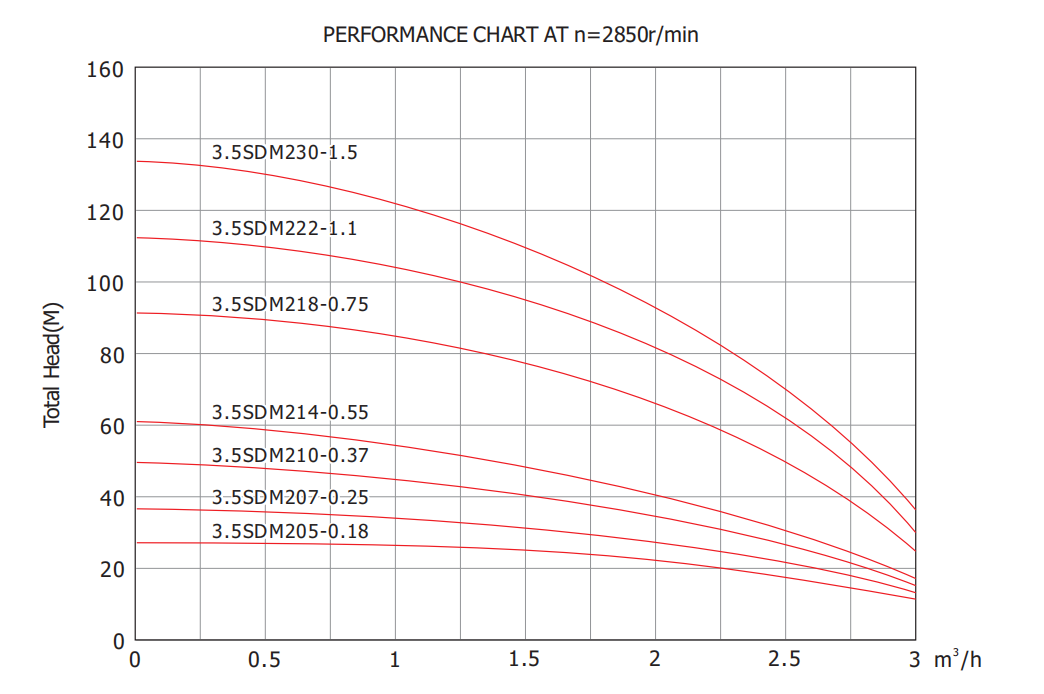

PERFORMANCE CHART

TECHNICAL DATA

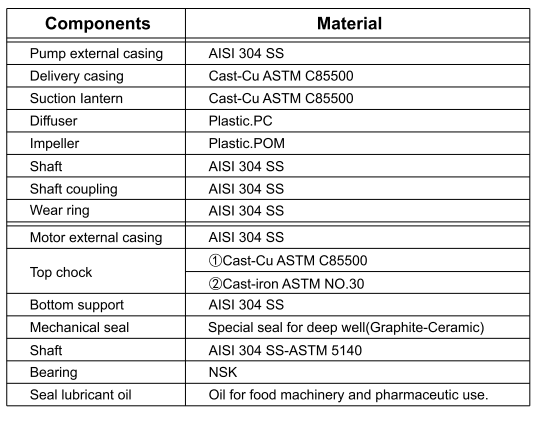

|

Model |

Power |

Delivery n=2850 r/min Outlet: G1" |

||||||||||

|

220-240V/50Hz |

kW |

HP |

Q |

m3/h |

0 |

0.5 |

1 |

1.5 |

1.8 |

2 |

2.5 |

3 |

|

L/min |

0 |

8 |

17 |

25 |

30 |

33 |

42 |

50 |

||||

|

3.5SDM205-0.18 |

0.18 |

0.25 |

H(m) |

28 |

27 |

26 |

25 |

23 |

22 |

17 |

11 |

|

|

3.5SDM207-0.25 |

0.25 |

0.33 |

39 |

37 |

36 |

34 |

32 |

26 |

23 |

13 |

||

|

3.5SDM210-0.37 |

0.37 |

0.5 |

50 |

49 |

47 |

45 |

38 |

32 |

28 |

15 |

||

|

3.5SDM214-0.55 |

0.55 |

0.75 |

61 |

60 |

58 |

50 |

40 |

35 |

32 |

17 |

||

|

3.5SDM218-0.75 |

0.75 |

1 |

91 |

90 |

88 |

76 |

62 |

52 |

48 |

25 |

||

|

3.5SDM222-1.1 |

1.1 |

1.5 |

112 |

110 |

107 |

95 |

78 |

64 |

58 |

30 |

||

|

3.5SDM230-1.5 |

1.5 |

2 |

133 |

130 |

127 |

112 |

90 |

76 |

69 |

36 |

||