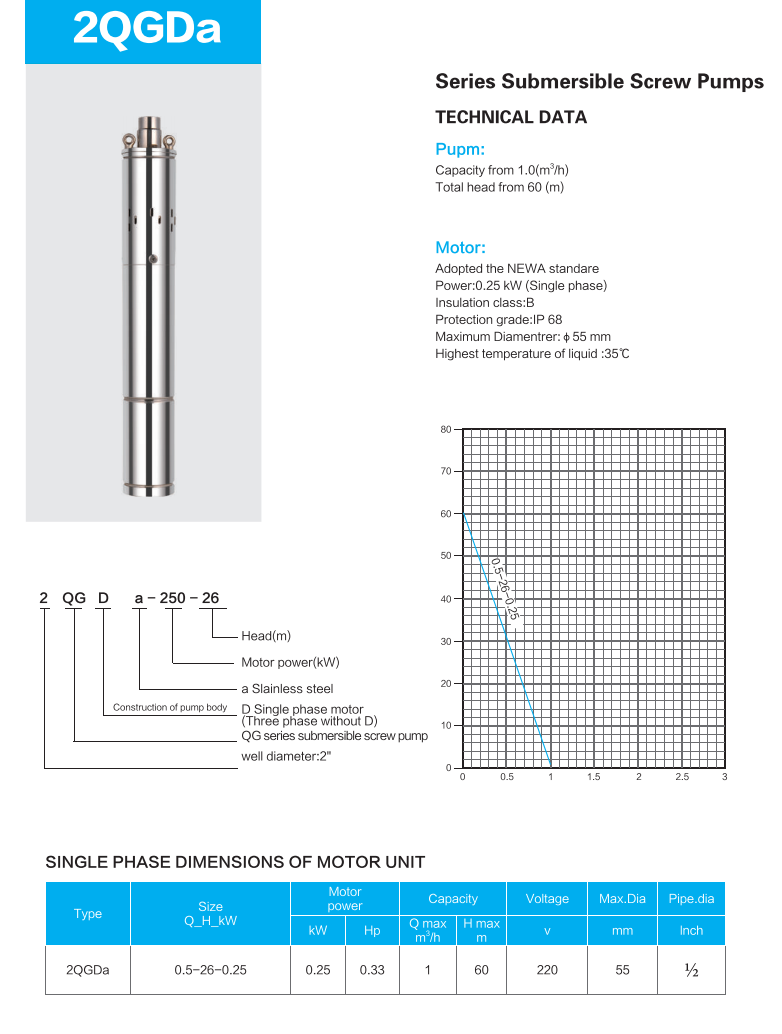

2QGDa china factroy for high quality water pumps

deep well pump is composed of three parts: working part including water inlet pipe, lifting pipe and upper well part( 1) The working part is composed of working parts, water inlet pipe parts, etc. The working parts are composed of upper, middle and lower guide housings, impellers, conical sleeves, bearings, impeller shafts and other parts. The impeller is closed and located in the middle guide housing (the number of middle guide housing depends on the number of stages of the pump). The lower guide housing is used to connect the middle guide housing and the water inlet pipe to smoothly guide the water flowing into the water inlet pipe into the first stage impeller. The water thrown by the first stage impeller is introduced into the second stage impeller through the middle guide housing, and the water thrown by the second stage impeller is then introduced into the third stage impeller through the second middle guide housing. The water will rise step by step, and the energy of the water will increase step by step. When the water flow is thrown out by the last stage impeller, it will enter the water lifting pipe through the upper diversion shell. A sealing ring is embedded on the shell for easy replacement after wear, and the shell is connected with bolts. The conical sleeve is used to fix the impeller on the pump shaft, and the rubber bearing is used to prevent the swing of the pump shaft and bear the axial force of the pump. A short pipe is installed at the upper end of the working parts to facilitate hoisting. The water inlet pipe is processed from a short pipe, and several round holes with a diameter of 10mm ~ 25mm are drilled around it to prevent sundries in the water from entering the impeller or blocking the water pump( 2) Lifting pipe part this part is composed of lifting pipe, transmission shaft, coupling, bearing body and other components. The lifting pipe of deep well pump is composed of several long pipe sections of equal length (each section is generally 2m ~ 2.5m long) and two short pipes at the top and bottom, which are connected with flanges. The transmission shaft is composed of several long shafts with equal length and two short shafts, which are connected by a coupling with internal thread. The connection between the pipe and the pipe is equipped with a bearing body with external thread and a rubber bearing of the transmission shaft. There is a chrome plated section on the transmission shaft, and the effective length of the chrome plated section is twice the length of the rubber bearing. When the chrome plated part of the transmission shaft is worn, the installation position of the short transmission shaft can be changed, and the short transmission shaft can be installed under the motor transmission shaft to move the transmission shaft down and continue to be used( 3) The well part is composed of pump seat and motor. The pump seat bears the weight of all lifting pipes and working parts. Gate valve and check valve can be installed at the water outlet of the pump seat as required and connected with the water outlet pipeline. The motor of deep well pump is mostly hollow shaft motor, which is a special motor for well pump. It is characterized by compact structure and high transmission efficiency.