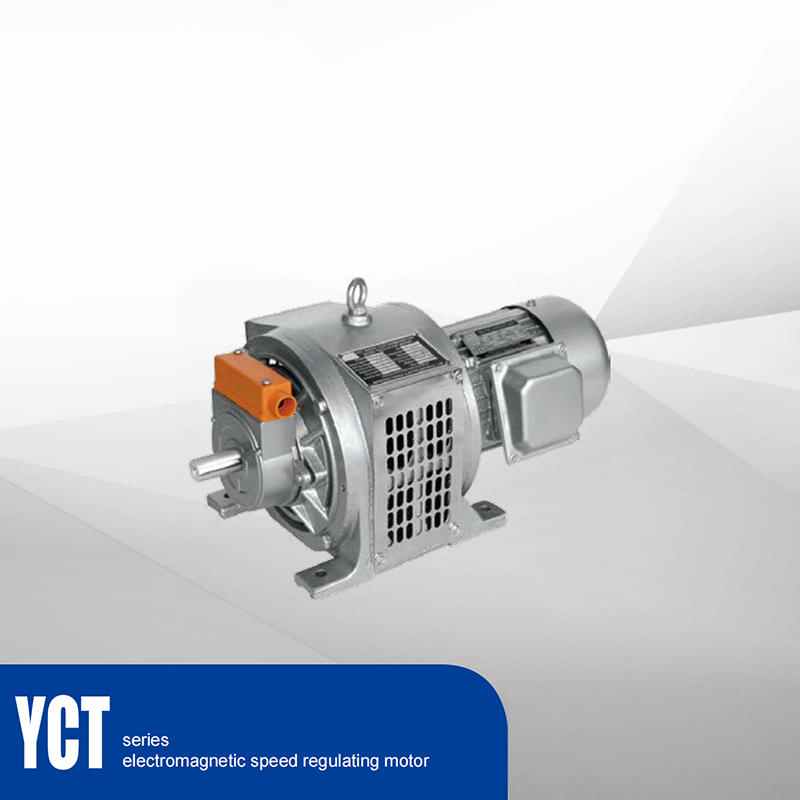

YCT series electromagnetic speed regulating motor

Product Overview

YCT series electromagnetic speed motor is an AC constant torque variable speed motor.Slip by the electromagnetic clutch,the drive motor and tachogenerator,usually with the JD,TXZ,CTK series controller composed of a set of exchange has a the velocimetry negative feedback system stepless drive , a wide speed smooth stepless speed regulation,it is with in China,s unified design new Electromagnetic Motor has the advantages of high efficiency,low noise ,vibration,high reliability,and aesthetic appearance.And in line with national international Electrotechnical Commission(IEC) standards.The series electromagnetic governor motor is widely applied in textile,printing and dyeing, A variety of food,chemical, paper, cement,rubber,plastics,cables, metallurgy,mining and other areas of constant torque stepless speed devices,especially for fans, pumps, load torque decreasing occasions,Controlled by the speed of adjustment to changes in flowor pressure to obtain a significant energy saving effect.

Electromagnetic speed regulating asynchronous motor is composed of ordinary squirrel cage asynchronous motor, electromagnetic slip clutch and electrical control device. The asynchronous motor is used as the prime mover. When it rotates, it drives the armature of the clutch to rotate together. The electrical control device is a device that provides the excitation current of the excitation coil of the slip clutch. The electromagnetic slip clutch is mainly introduced here, and its structure is shown in Figure 2-19. It includes armature, magnetic pole and excitation coil. The armature is a cylindrical structure made of cast steel, which is connected with the rotating shaft of squirrel cage asynchronous motor, commonly known as the active part; The magnetic pole is made into a claw structure and installed on the load shaft, commonly known as the driven part. There is no mechanical connection between the driving part and the driven part. When the excitation coil passes through the current, a magnetic field is generated, and the claw structure forms many pairs of magnetic poles. At this time, if the armature is dragged and rotated by the squirrel cage asynchronous motor, it will cut the magnetic field interaction and generate torque, so the magnetic pole of the driven part will rotate with the armature of the driving part. The speed of the former is lower than that of the latter, because the armature can cut the magnetic line of force only when there is relative movement between the armature and the magnetic field. There is no essential difference between the principle that the magnetic pole rotates with the armature and the principle that the rotor of an ordinary asynchronous motor moves with the rotating magnetic field of the stator winding. The difference is that the rotating magnetic field of the asynchronous motor is generated by the three-phase AC in the stator winding, while the magnetic field of the electromagnetic slip clutch is generated by the DC current in the excitation coil, And because the armature rotates, it plays the role of rotating magnetic field. 1 - prime mover, 2 - working air gap, 3 - main shaft, 4 - output shaft, 5 - magnetic pole, 6 - mechanical characteristics of armature electromagnetic slip clutch can be approximately expressed by the following empirical formula: n = n0-kt2 / i4f, where: N0 - speed of driving part of clutch (squirrel cage motor); N - speed of the driven part (magnetic pole) of the clutch; If

Library linear motor - Dongfang motor The advertisement is directly operated by Dongfang motor of Japan. The linear motor is thin, high rigidity and high precision. The linear motor is directly corresponding to the special free software, View details >

- excitation current; K - coefficient related to clutch structure; T - electromagnetic torque of clutch. When running stably, the load torque is equal to the electromagnetic torque of the clutch.

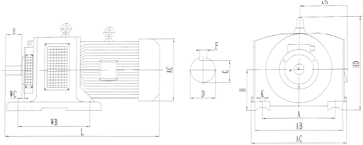

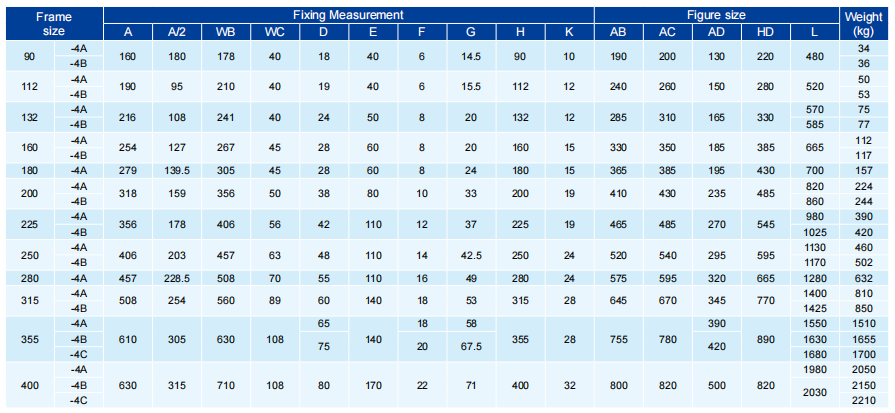

Installation Dimension

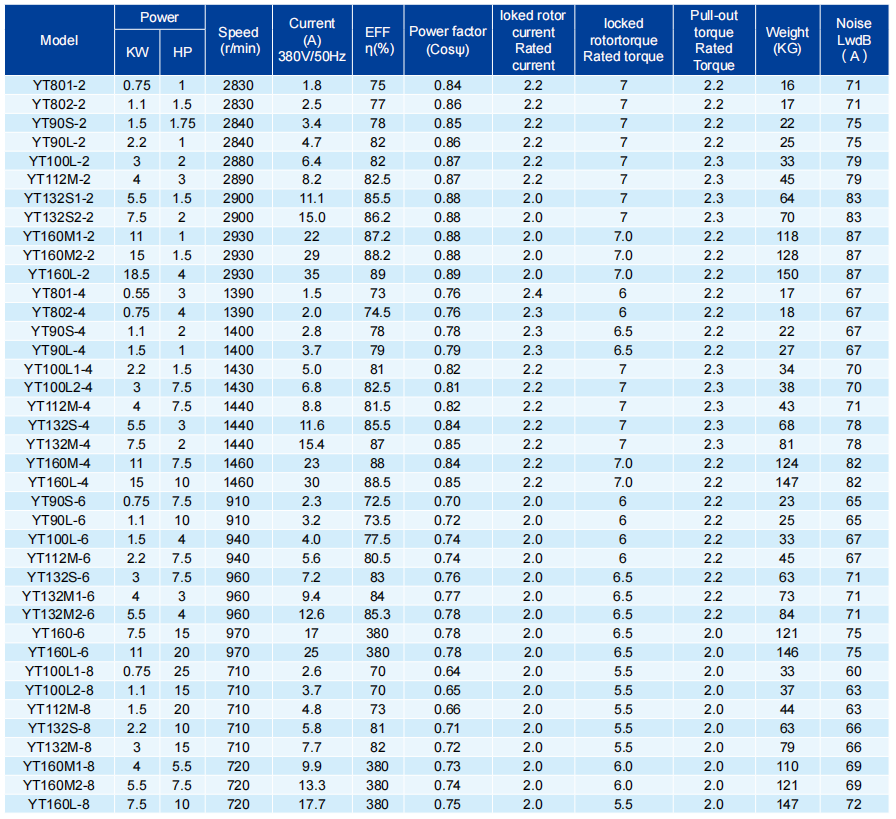

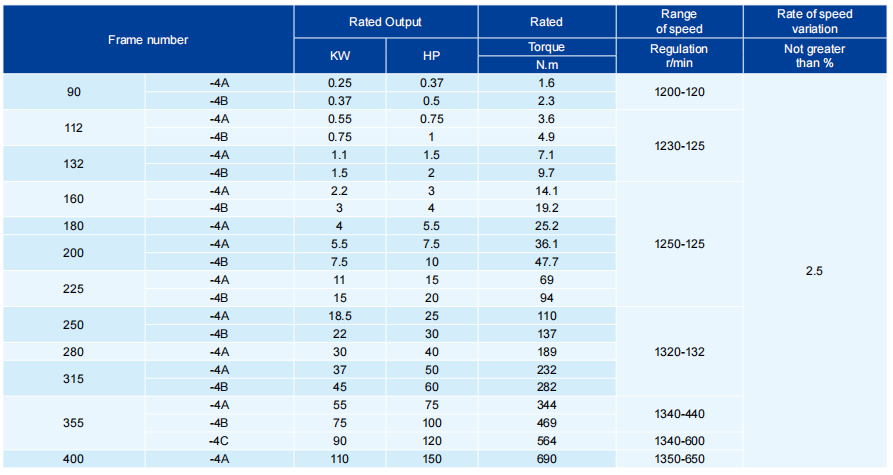

Technical Parameter

Technical Parameters