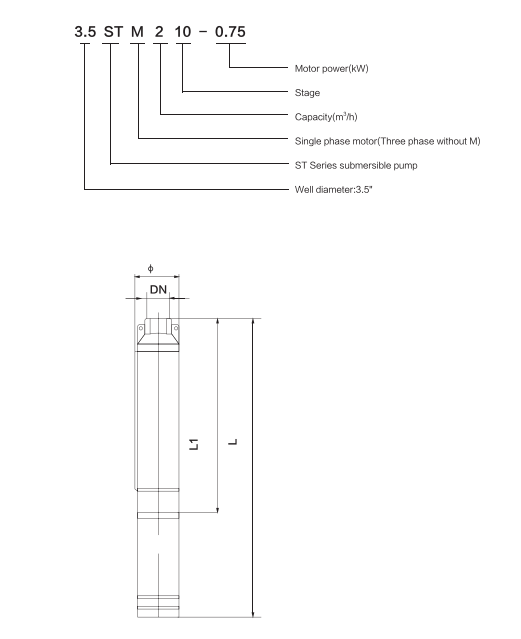

3.5″STM2 deep well pump submeersible water pump

The biggest feature of deep well pump is that it integrates motor and pump. It is a pump immersed in underground water wells for pumping and conveying water. Stainless steel deep well pump is widely used in farmland drainage and irrigation, industrial and mining enterprises, urban water supply and drainage and sewage treatment. There are no special requirements for well pipe and lifting pipe (i.e. steel pipe well, ash pipe well, earth well, etc; Under the permission of pressure, steel pipe, rubber pipe and plastic pipe can be used as lifting pipe). The installation, use and maintenance of deep well pump are convenient and simple, and the floor area is small, so there is no need to build pump house.

The stainless steel submersible sewage pump contained in the stainless steel submersible pump has been widely used in shopping malls in recent years. It is respected by a wide range of users because of its corrosion resistance, long service life, light weight, safety and health. Moreover, compared with ordinary sewage pumps, the price of brown metal has been almost the same because of its continuous increase in price over the years. The stainless steel data used in the future belong to green environmental protection data, which can be recovered again. Therefore, it has become the leader of stainless steel high temperature and corrosion-resistant submersible pump in recent years. Especially in recent years, countries have put forward higher requirements for food industry. Due to safety and health, stainless steel materials have gradually stepped onto the historical stage. With regard to hard requirements, stainless steel pump products represented by stainless steel submersible pumps have begun to shine in food products.

Nowadays, stainless steel submersible pump is widely used in agriculture. It can not only improve agricultural work efficiency, but also reduce labor consumption. It is a very economical product for many large agricultural households. However, the vast number of farmers do not understand the stainless steel submersible pump, and there are problems in its maintenance and even its application methods, which will greatly reduce the service life and work efficiency of the pump. Let me talk about some precautions in the application of stainless steel submersible pump.

1. Do not start frequently

Stainless steel submersible pump should not be started frequently, because there will be backflow when the pump is stopped, and immediate start will make the motor load start.

2. The voltage is abnormal and should not be started

When the voltage is too high or too low, the temperature of the pump will be too high, and then shorten its service life and even burn it out.

3. Shut down immediately in case of abnormality

When using stainless steel submersible pump, it is necessary to take care of the personnel nearby. In case of abnormality, it shall be stopped immediately and the pump shall not be turned for inspection.

4. Start up regularly

When the pump is not used for a long time, we should start it regularly to prevent rust. It is generally better to open it once a week.

Operating and condition

Minimum well diameter: 3.5 inches

Maximum fluid temperature: 35 oC

Maximum sand content: 0.25%

Maximum immersion: 30m

Impeller: Nylr

Diffuser: Engineering plastic+ss cover

Cover: AISI304/ Steel

Motor

Power:0.25 to 1.1kw(Single phase) Insulation class:B

Protection grade:IP68

Maximum diameter: 75mm

Highest temperature of liquid:35*C