V(WQ) Submersible Pump Stainless Steel Centrifugal Clean Water Pump With Float Switch

WQZ series self-flushing stirring-type submergible sew-age pump is a renewal product on the basis of model WQ submergible sewage pump and the design principle of it comes as drilling several reverse flushing water holes on the pump casing so as to get partial pressurized water inside of the casing, when the pump is at work, through these holes and, in a divergent state, flushing onto the bottom of a sewagepool,the huge flushing force produced therein makes the depositson the said bottom up and stirred, then mixed with sewage, sucked into the pump cavity and drained out finally. In addition to the excellent performance with model WQ sewage pump,this pump can also prevent the deposits from depositing on a pool bottom to purify the pool without need of periodic clear-up, saving the cost on both labor and material.

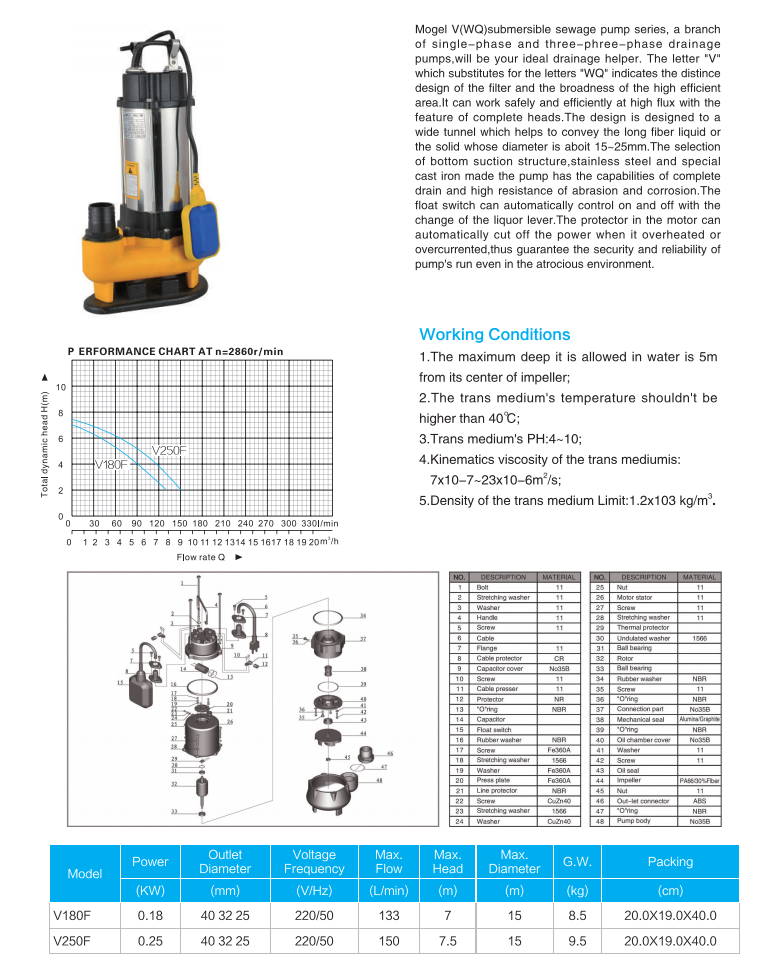

CONDITIONS OF USE 140 1050kg/ 3mPH5-9

1. The medium temperature should not be over 40,3the density 1050kg/m, and the PH value within 5-9.

2. During running, the pump must not be lower than thelowestliquidlevel,seelowest liquid levelin the drawingof installation dimensions(covering the automatic coolingsystem), means lowest liquid level without no automaticcooling system

3. Rated voltage 380V, rated frequency 50HZ, the motorcan run successfully only under the condition the deviationsof both rated voltage and frequency are not over 5%.

4. The maximum diameter of the solid grain going thro-ugh the pump has not to be larger than 50% of that of thepump outlet

The impeller rotates CCW as viewed from the suction

Bearing:

Impoted SKF or NTN bearing, which, with a reasonableconfiguration, can oxtend the duration of the pump.

Cooling:Thebuit-incoolingsystemcanhavethepumpnormallywork whether the motor is on or under the liquidsurface. Apart of the liquid is extracted to bring out the beat producedby the motor from the pump circulation to the cooling barreland to the pump casing and, when external cooling is required,the cooling sleeve may be separated from the pump casing and individually connected to the cooling system.

Motor:Of F classinsulation,max.workingtemperature 155,and of a protective grade IPX8 with the effective seal.

Mechanical seal:UseBogmanmechanicalsealofGermany,twowaysofthe seal are in series with each other and individually workto separate the motor from the pump seal to provide the motorwith a dual protection.

Thesealingmaterialonthepump side is tungsten carbide/silicon carbide while on the motor side, graphite/tungstencarbide.

Oil chamber: Oil can lubricate and cool the mechanical seal and real-ize the attached function of safety by preventing liquid frompenetrating into the motor.The air of a certain amount leftinside of the chamber can lower the pressure accumulatively

raised.

3. Rated voltage 380V, rated frequency 50HZ, the motorcan run successfully only under the condition the deviationsof both rated voltage and frequency are not over 5%.

4. The maximum diameter of the solid grain going thro-ugh the pump has not to be larger than 50% of that of thepump outlet.

During running, the pump must not be lower than thelowestliquidlevel,seelowest liquid levelin the drawingof installation dimensions(covering the automatic coolingsystem),