SELF-PRIMING PUMP JDW/1A, DP255

Before installation, check whether the fasteners of the unit are loose and whether the pump body, impeller and flow channel are blocked by foreign matters, so as to avoid the impeller and pump body and affecting the service performance of the pump under working conditions. 2. During installation, the weight of suction pipe and discharge pipe shall not be on the pump, and the pump body itself is not allowed to bear the load of the pipeline to avoid deformation of the pump body. 3. The installation height of the suction inlet shall not exceed 5m. When permitted, the installation height of the suction inlet shall be lower than the lowest water storage level of the pool as far as possible, and the length of the suction pipe shall be shortened as far as possible with fewer elbows, which is conducive to shortening the self-priming time and improving the self-priming function. 4. Valves and flanges in the suction pipeline shall be strictly prevented from air leakage or liquid leakage, that is, air leakage is not allowed in the suction pipeline. 5. In order to maintain a certain storage liquid in the pump body, achieve high self-priming capacity and prevent dry friction of the mechanical seal, the inlet of the pump must be higher than the pump axis. 6. In order to facilitate maintenance and safe use, a regulating valve is installed on the inlet pipeline of the pump and a pressure gauge is installed near the pump outlet to ensure operation within the rated head and flow range, ensure normal operation of the pump and increase the service life of the pump. 7. When installing the pump, the electrostatic grounding resistance of the pump pipeline shall meet the specified requirements. 8. Correct the clearance and coaxiality of pump coupling and motor coupling, and the allowable deviation of different axial degrees is 0.1mm. The height difference between pump shaft and motor can be adjusted by padding copper or iron sheet on the bottom corner. 9. After installation, move the pump shaft, the impeller shall be free of friction or jamming, and the pump shall be disassembled to check the cause. 10. After the actual operation of the unit for 3-4 hours, the final inspection shall be carried out. If there are no defects, it is considered that the installation is proper. The temperature of the bearing shall be checked during the test run, and the temperature of the bearing body shall not exceed 70 ℃.

JDW/1A

DP255

INTRODUCTION

self-priming deep-well pump consist of an ejector unit and a centrifugal pump. The ejector can be put in a 4''diameter well. These pumps are suitable to convey clean water or non-aggressive chemical fluids. They are suitable to pump water from deep well and supply water automatically by pressure tank and pressure control. It is always advisable to install a foot vale with a strainer on the bottom of inlet pipe

MOTOR

Degree of protection: IP54

Insulation class: F

Continuous operation

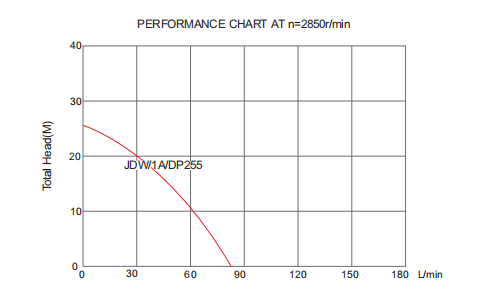

PERFORMANCE CHART

TECHNICAL DATA

|

Model |

Power |

Max.head (m) |

Max.flow (L/min) |

Max.suct (m) |

Inlet / Outlet |

|

|

(Kw) |

(Hp) |

|||||

|

JDW/1A |

0.75 |

1.0 |

25 |

80 |

25 |

1 1/4" X 1" X 1" |

|

DP255 |

0.75 |

1.0 |

25 |

80 |

25 |

1 1/4" X 1" X 1" |