S150A duplex stainless steel submersible deep well pump

Deep well pump is a vertical multistage centrifugal pump, which can lift water from deep wells. With the decline of groundwater level, deep well pumps are more widely used than general centrifugal pumps. However, due to improper selection, some users have problems such as unable to install, insufficient water, unable to pump water, and even damage the well. Therefore, how to select deep well pump is particularly important( 1) The pump type is preliminarily determined according to well diameter and water quality. Different types of pumps have certain requirements for the size of well diameter, and the maximum overall dimension of the pump shall be less than the well diameter of 25 ~ 50mm. If the well hole is skewed, the maximum overall dimension of the pump shall be smaller. In short, the pump

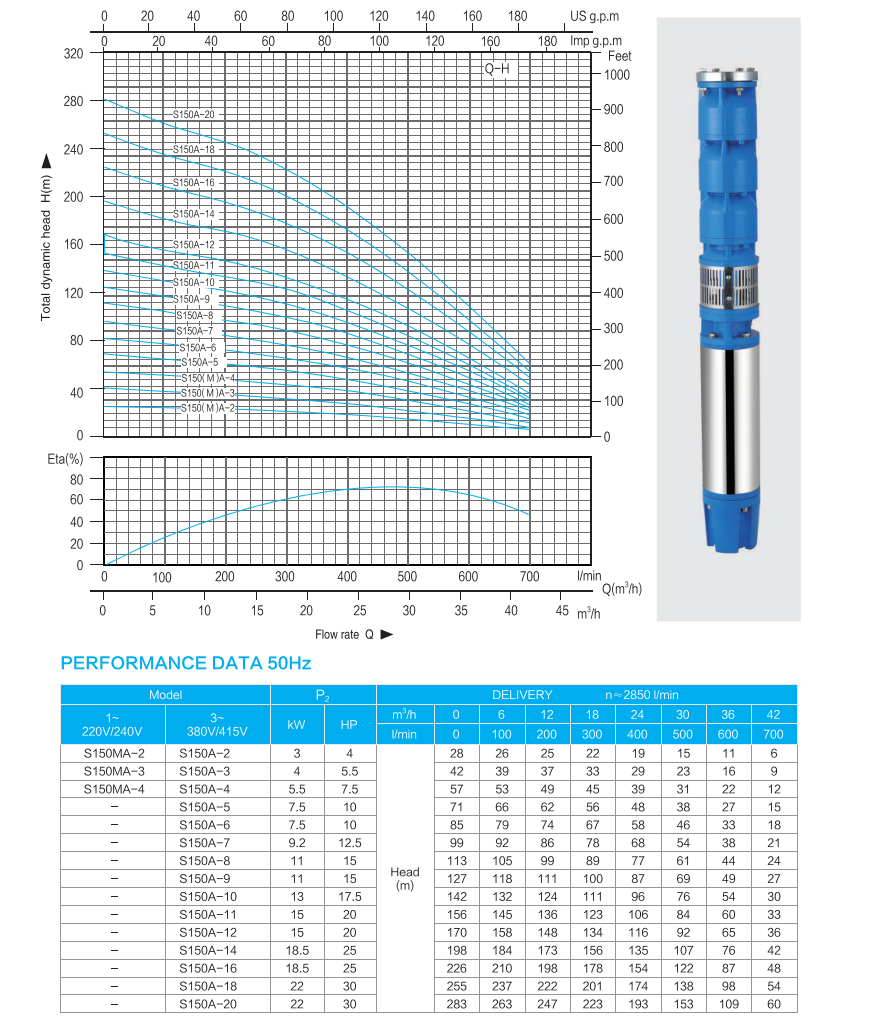

The body part shall not be close to the inner} wall of the well, so that the well will be damaged by the vibration of the waterproof pump. (2) select the flow of well pump according to the water output of well. Each well has an economically optimal water output, and the flow of the pump shall be equal to or less than the water output when the water level of the motor well drops to half of the well water depth. When the pumping capacity is greater than the pumping capacity of the well, it will cause the collapse and deposition of the well wall and affect the service life of the well; If the pumping capacity is too small, the efficiency of the well will not be brought into full play. Therefore, the best way is to conduct pumping test on the mechanical} well, and take the maximum water output that the well may provide as the basis for selecting the well pump flow. Water pump flow, with brand model

Or the number marked on the statement shall prevail. (3) according to the falling depth of the well water level and the head loss of the water transmission pipeline, determine the actual required head of the well pump, that is, the head of the well pump, which is equal to the vertical distance (net head) from the water level to the water surface of the outlet tank plus the lost head. The loss head is usually 6 ~ 9% of the net head, usually 1 ~ 2m. The water inlet depth of the lowest stage impeller of the water pump should be 1 ~ 1.5m. The total length of the part under the pump tube well shall not exceed the maximum length of} entering the well specified in the pump manual. (4) deep well pumps should not be installed for wells with well water sediment content exceeding 1 / 10000. Because the sand content of well water is too large, such as When it exceeds 0.1%, it will accelerate the wear of rubber bearing, cause vibration of water pump and shorten the service life of water pump.

Applications

For water supply from wells or reservoir

For domestic use, for civil and industrial application

For garden use and irrigation

Operating conditions

Maximum fluid temperature up to +50*C

Maximum sand content:0.5%

Maximum immersion:100m.

Minimum well diameter:6"

Options on request

Special mechanical seal

Other voltages or frequency 60Hz

Warranty:1 year

(according to our general sales conditions).