Cut/MMA-100 Eco 380V 19.5kVA 4-5bar Customized Plasma Welder Pilot Central Carbon Steel Cutting Machine

Plasma is a gas heated to extremely high temperature and highly ionized. It will transfer the arc power to the workpiece. The high heat will melt and blow off the workpiece to form the working state of plasma arc cutting. After the compressed air enters the cutting torch, it is distributed by the gas chamber to form plasma gas and auxiliary gas. The plasma gas arc melts the metal, while the auxiliary gas cools all parts of the cutting torch and blows away the melted metal. The cutting power supply includes two parts: main circuit and control circuit. The electrical principle block diagram is shown in the figure: the main circuit includes contactor, three-phase power transformer with high leakage reactance, three-phase bridge rectifier, high-frequency arc striking coil and protective elements. High leakage reactance leads to steep external characteristics of power supply. The control circuit completes the whole cutting process through the button switch on the cutting torch: pre ventilation – main circuit power supply – high frequency arc striking – cutting process – arc stopping – stop. The power supply of the main circuit is controlled by the contactor; The opening and closing of gas is controlled by solenoid valve; The control circuit controls the high frequency oscillator to ignite the arc, and stops the high frequency after the arc is established. In addition, the control circuit also has the following internal locking functions: 1. The thermal control switch acts and stops working. Cutting fault 1) incomplete cutting: A: the thickness of the plate exceeds the applicable range of the equipment. B: cutting speed is too fast. C: the inclination of the cutting torch is too large. D: the compressed air pressure is too high or too low. E: the grid voltage is too low. 2) unstable plasma arc: A: the cutting torch moves too slowly. B: the two-phase power supply reduces the working voltage. C: the compressed air pressure is too high

| ITEM | UNIT | CUT/MMA-100 EXTRA | CUT/MMA-100 ECO |

| Input Power Voltage | V | 380V,3Ph | |

| Frequency | Hz | 50/60 | |

| Rated Input Capacity | KVA | 15 | |

| Real Output Current (MMA) | A | 20-280 | |

| Real Output Current (CUT) | A | 20-105 | |

| No-Load Voltage | V | 280 | |

| Rated Duty Cycle (25 degree) | % | 60% | |

| Power Factor | COS | 0.93 | |

| Air Pressure | Bar | 4–5 | |

| Temperature Protection | 75 degree | ||

| Protective Grade of Housing | IP23 | ||

| Suitable For Electrode | mm | 1.6-4.0 | |

| Max Cutting Thickness | mm | 50 | |

| Clean Cutting Thickness | mm | 28 | |

| Power Supply Cable | 4 mm2,4core with 3 meters | ||

| Plug | industrial 5 pin plug | without plug | |

| Cutting Torch | A101 central connect torch | P80 torch | |

| Wheel size | 1.5 inch | ||

| Machine Size | cm | 51*25*56.5 | |

| Packing Size | cm | 62*32.5*63.5 | |

| G.W | Kg | 35 | |

| N.W | Kg | 28 | |

| Generator Friendly | yes,above 30 Kw | ||

Standard Packing List

Features:

-Adopt advanced IGBT Module Technology

-Un-touch start system

-Rapid arc strike

-Competitive Cutting Thickness

-Cool Operation,Long consumable life

-Engine drive compatible

-Energy saving

-Rapidaly cutting materials like Broze,Ss,Metal and so on

Accessories: 4 meters A101 central connector cutting torch,regulator,mask,brush,tube.3 meters welding clamp,3 meters earth clamp

OUTLOOKS FOR CUT-100 XTRA ,CUT-100 ECO AND CUT-120 ECO ARE SIMILAR

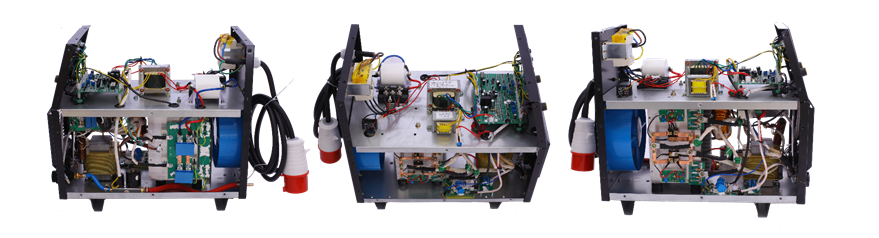

INSIDE STRUCTURE VIEW

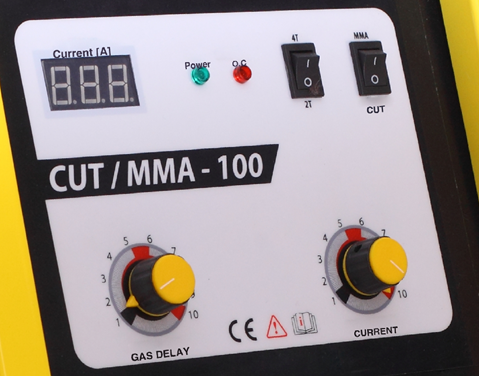

ENLARGE VIEW OF FRONT PANEL