plasma cutting machine CUT/MMA-100

Plasma arc cutting uses the heat of high-temperature plasma arc to locally melt (and evaporate) the metal at the workpiece notch

A processing method that uses the momentum of high-speed plasma to remove molten metal to form a notch. Plasma cutting does not fit well

The same working gas can cut all kinds of metals that are difficult to cut with oxygen, especially for non-ferrous metals (stainless steel, aluminum

Copper, titanium and nickel) have better cutting effect; Its main advantage lies in the plasma cutting speed when cutting metal with small thickness

Fast, especially when cutting ordinary carbon steel sheet, the speed can reach 5 times that of oxygen cutting method 6 times, smooth cutting surface, small thermal deformation and low

Less heat affected zone. Plasma cutting machines are widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry and general machines

Machinery, engineering machinery, steel structure, shipbuilding and other industries.The utility model relates to a novel multifunctional isochronous

The sub cutting machine is provided with a through hole, a driving roller and a positioning roller, so that the cylindrical workpiece can be placed at the top of the driving roller, and

Start the positioning hydraulic cylinder to make the positioning hydraulic cylinder drive the positioning frame to rotate, so as to drive the positioning roller to clamp the workpiece and realize alignment

At the same time, the plasma cutting gun is started to cut the cylindrical workpiece at the bottom, and the plate shape can be

The workpiece is placed on the top of the cutting machine, and the plasma cutting gun is started to cut the plate workpiece, so that the cutting machine can

Cutting the plate workpiece can also cut the circular workpiece, which effectively improves the application range of the cutting machine and avoids

The current plasma cutting machine has poor applicability and can only cut a single type of workpiece.

| ITEM | UNIT | CUT/MMA-100 EXTRA in-built compressor | CUT/MMA-100 ECO in-built compressor |

| Input Power Voltage | V | 380V,3Ph | |

| Frequency | Hz | 50/60 | |

| Rated Input Capacity | KVA | 15 | |

| Real Output Current (MMA) | A | 20-280 | |

| Real Output Current (CUT) | A | 20-105 | |

| No-Load Voltage | V | 280 | |

| Rated Duty Cycle (25 degree) | % | 60% | |

| Power Factor | COS | 0.93 | |

| Compressor power | W | 1500 | |

| Air Pressure | Bar | 3–4.5 | |

| Temperature Protection | 75 degree | ||

| Protective Grade of Housing | IP23 | ||

| Suitable For Electrode | mm | 1.6-4.0 | |

| Max Cutting Thickness | mm | 40 | |

| Clean Cutting Thickness | mm | 25 | |

| Power Supply Cable | 4 mm2,4core with 3 meters | ||

| Plug | industrial 5 pin plug | without plug | |

| Cutting Torch | A101 central connect torch | P80 torch | |

| Wheel size | 1.5 inch | ||

| Machine Size | cm | 62.5*32.5*63.5 | |

| Packing Size | cm | 76*42*73 | |

| G.W | Kg | 64 | |

| N.W | Kg | 61 | |

| Generator Friendly | yes,above 30 Kw | ||

Standard Packing List

Features:

-Adopt advanced IGBT Module Technology

-Air Compressor in-built ,oil free and silence pump , also external compressor can be matched once needed

-Untouch start system

-Rapid arc strike

-Competitive Cutting Thickness

-Cool Operation,Long consumable life

-Engine drive compatible

-Energy saving

-Rapidaly cutting materials like Broze,Ss,Metal and so on

Accessories: 4 meters A101 central connector cutting torch,regulator,mask,brush,tube.3 meters welding clamp,3 meters earth clamp

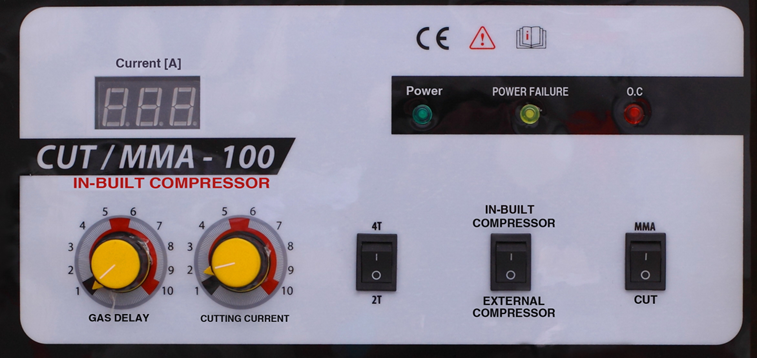

OUTLOOKS FOR CUT-100 XTRA IN-BUILT COMPRESSOR

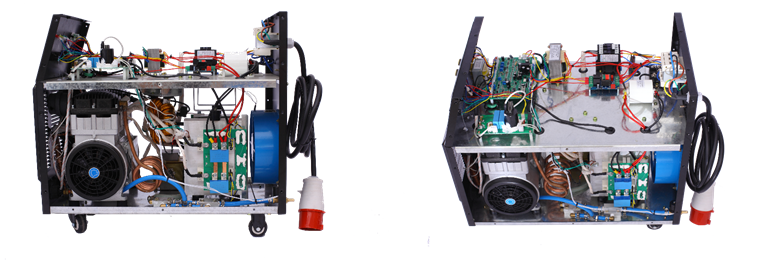

INSIDE STRUCTURE VIEW

ENLARGE VIEW OF FRONT PANEL