CENTRIFUGAL PUMP

Centrifugal pump is a machine used to transport liquid and increase liquid energy.

Compared with other types of pumps, centrifugal pump has many advantages, such as uniform flow, stable operation, low vibration, high speed, low equipment installation and maintenance cost and wide application range (including flow, head and adaptability to medium properties). Therefore, centrifugal pump is widely used in industrial production.

Centrifugal pump is a machine used to transport liquid and increase liquid energy.

Compared with other types of pumps, centrifugal pump has many advantages, such as uniform flow, stable operation, low vibration, high speed, low equipment installation and maintenance cost and wide application range (including flow, head and adaptability to medium properties).

1、 Classification by number of working impellers

1. Single stage pump: that is, there is only one impeller on the pump shaft.

2. Multistage pump: that is, there are two or more impellers on the pump shaft. Single stage centrifugal pump , multistage centrifugal pump , II. Classified according to working pressure , low pressure pump, medium pressure pump and high pressure pump. III. classification according to impeller water inlet mode

1. Single side water inlet pump: also known as single suction pump, that is, there is only one water inlet on the impeller; 2. Double side water inlet pump: also known as double suction pump, that is, there is a water inlet on both sides of the impeller. Single side water inlet pump ^ double side water inlet pump ^ IV. classification according to pump shaft position

1. Horizontal pump: the pump shaft is in the horizontal position. 2. Vertical pump: the pump shaft is in the vertical position. Horizontal pump vertical pump

Basic structure of centrifugal pump} single stage single suction centrifugal pump features:

Single stage single suction centrifugal pump has the advantages of reliable operation, simple structure, easy manufacturing and processing, convenient maintenance and strong adaptability. It is a widely used centrifugal pump. One end of the pump is supported by a bearing in the bracket, and the other end equipped with an impeller is cantilevered out of the bracket.

According to the different split positions of pump body and pump cover, it can be divided into front open and rear open structures. The advantage of rear open pump is that during maintenance, the bracket can be taken out together with the impeller as long as the bracket stop nut is loosened, and it is not necessary to disassemble the liquid inlet and discharge pipelines of the pump.

APPLICATION

For pumping dean liquids without abrasive particles, which are chemically non aggressive to the pump materials

For water supply

For heating, air-conditioning, cooling and circulation plants

For civil and industrial applications

For firefighting applications

For irrigation

The pump should be installed in an enclosed environment or sheltered from inclement weather

MOTOR

Two-pole induction motor,50Hz (n=2850 rpm)

Single phase 220V-240V,maximum 2.2 kw

Three phase 380V-415V

With thermal protector incorporated into the winding

Insulation class:F

Protection:IP55

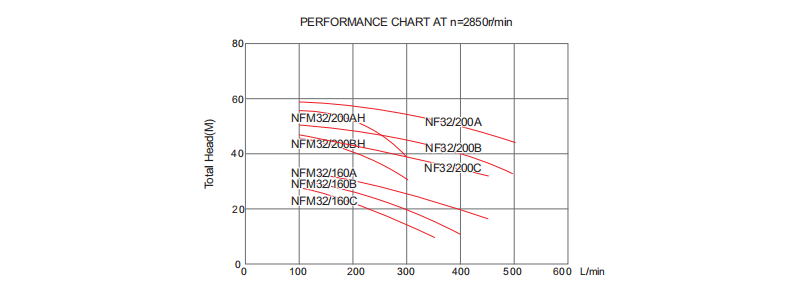

PERFORMANCE CHART

TECHNICAL DATA

|

Model |

Power |

Q |

m3/h |

6 |

9 |

12 |

15 |

18 |

21 |

24 |

27 |

30 |

||

|

Single phase |

Three phase |

(Kw) |

(Hp) |

L/min |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

|

|

NFM32/160C |

|

1.50 |

2.00 |

H(m) |

27 |

24 |

21 |

18 |

15 |

14 |

/ |

/ |

/ |

|

|

NFM32/160B |

|

2.20 |

3.00 |

29 |

27 |

26 |

25 |

20 |

17 |

16 |

/ |

/ |

||

|

NFM32/160A |

|

3.00 |

4.00 |

33 |

31 |

30 |

29 |

28 |

20.5 |

19 |

18 |

/ |

||

|

NFM32/200BH |

NF32/200BH |

3.00 |

4.00 |

45 |

42 |

39 |

34 |

28 |

/ |

/ |

/ |

/ |

||

|

NFM32/200AH |

NF32/200AH |

4.00 |

5.50 |

54 |

52 |

49 |

44 |

38 |

/ |

/ |

/ |

/ |

||

|

NFM32/200C |

NF32/200C |

4.00 |

5.50 |

44 |

43 |

42 |

40 |

38 |

36 |

34 |

32 |

/ |

||

|

|

NF32/200B |

5.50 |

7.50 |

52 |

51 |

49 |

47 |

45 |

43 |

41 |

38 |

36 |

||

|

|

NF32/200A |

7.50 |

10.00 |

58 |

57 |

56 |

55 |

53 |

52 |

50 |

47 |

44 |

||