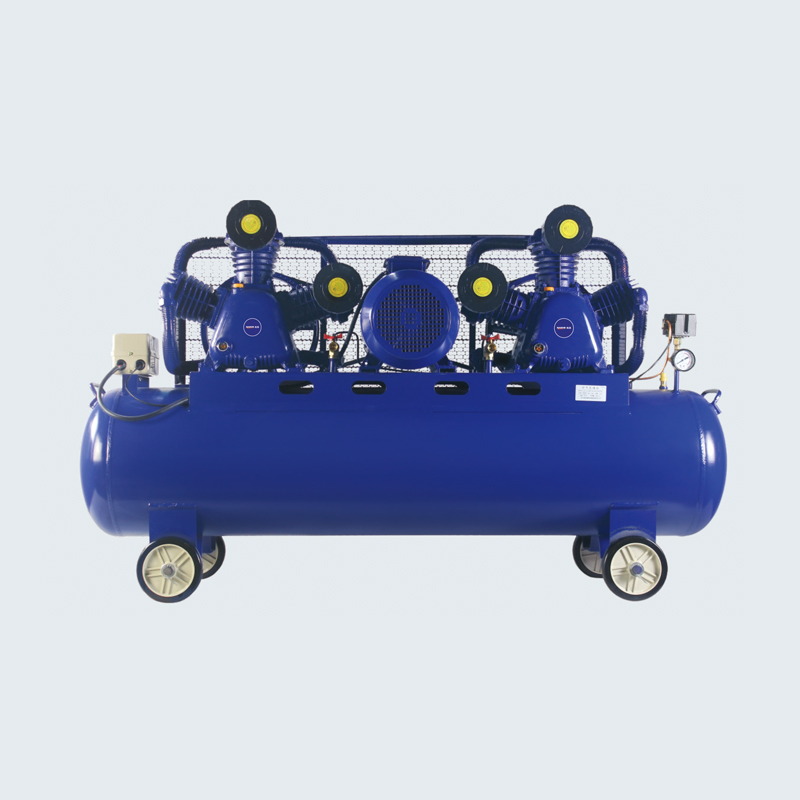

Belt air compressor two pump head big air delivery

When the crankshaft of the piston air compressor rotates, the piston moves back and forth through the transmission of the connecting rod, and the working volume composed of the inner wall of the cylinder, the cylinder head and the top surface of the piston will change periodically. When the piston of the piston air compressor starts to move from the cylinder head, the working volume in the cylinder gradually increases. At this time, the gas pushes the inlet valve along the inlet pipe and enters the cylinder until the working volume becomes larger, and the inlet valve is closed; When the piston of the piston air compressor moves in the opposite direction, the working volume in the cylinder decreases and the gas pressure increases. When the pressure in the cylinder reaches and is slightly higher than the exhaust pressure, the exhaust valve opens and the gas is discharged from the cylinder until the piston moves to the limit position, and the exhaust valve closes. When the piston of the piston air compressor moves in the opposite direction again, the above process repeats. In short, the crankshaft of the piston air compressor rotates once, the piston reciprocates once, and the process of intake, compression and exhaust is realized successively in the cylinder, that is, a working cycle is completed. Advantages of piston air compressor (1) the required pressure can be obtained regardless of the flow, with a wide range of exhaust pressure, and the higher pressure can reach 320MPa (industrial application), or even 700MPa (in the laboratory); (2) the single machine capacity is any flow below 500m3 / min; (3) within the general pressure range, the requirements for materials are low. Ordinary steel materials are mostly used, which is easy to process and low cost; (4) the thermal efficiency is high. Generally, the thermal insulation efficiency of large and medium-sized units can reach about 0.7 ~ 0.85; (5) when adjusting the gas volume, it has strong adaptability, that is, it has a wide exhaust range, is not affected by the pressure, and can adapt to a wide pressure range and refrigeration capacity requirements; (6) the weight and characteristics of gas have little impact on the working performance of air compressor, and the same air compressor can be used for different gases;

What are the models of positive pressure air respirators?

The common models of positive pressure air respirators include rhzkf6.8/30, rhzkf9 / 30 and rhzkf6.8/30-2. From the above models of positive pressure air respirators, we can find that RHZ

(7) the driving machine is relatively simple, and most of them adopt motor, which generally does not adjust speed and has strong maintainability;

(8) the piston air compressor is technically mature and has accumulated rich experience in production and use;