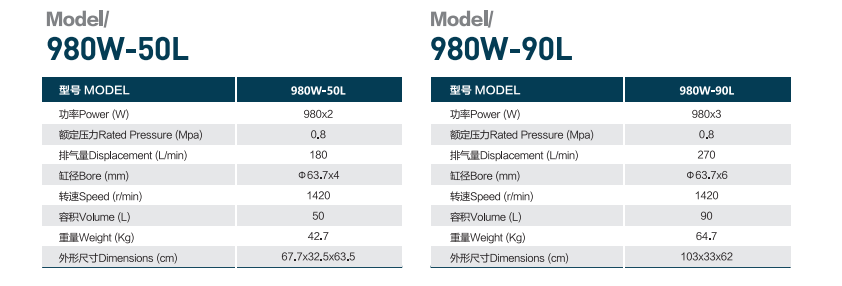

980W Silent Oil-free Air Compressor

Working principle of main engine of oil-free air compressor: when the motor drives the compressor crankshaft to rotate, through the transmission of connecting rod, the piston with self lubrication without adding any lubricant will move back and forth, and the working volume composed of cylinder inner wall, cylinder head and piston top surface will change periodically. When the piston of the piston compressor starts working from the cylinder head, the working volume in the cylinder will gradually increase, and then the gas will push the inlet valve along the inlet pipe and enter the cylinder. When the working volume becomes the maximum, the inlet valve will be closed; The piston of the piston compressor moves in the opposite direction, and then the exhaust valve closes. The general working process is: the crankshaft of the piston compressor rotates once, the piston reciprocates once, and the process of intake, compression and exhaust is realized successively in the cylinder, that is, a working cycle is completed. The structural design of single shaft and double cylinder makes the gas flow of the compressor twice that of a single cylinder at a certain rated speed, and has been well controlled in vibration and noise control. The last reference standard is whether the technical parameter identification of the machine is complete and qualified. The parameters identified according to international practice include metric units and American units. Generally speaking, manufacturers with simple parameter identification do not have relevant testing equipment, and some parameters can not meet the general technical standards. Therefore, it is recommended that you ask the manufacturer to provide detailed parameters so that you can make a correct choice.