4STm stainless high quality submersible water pumps

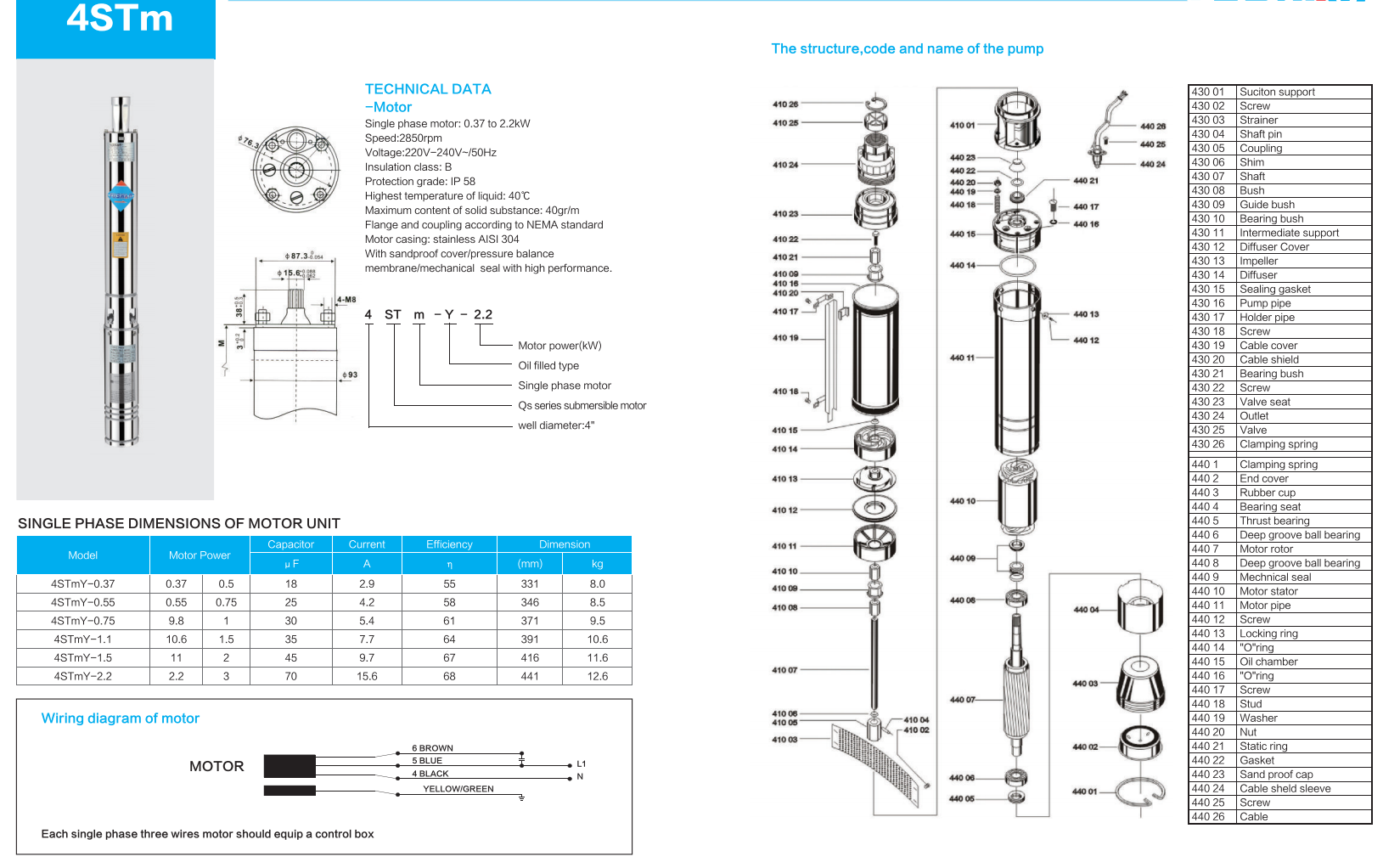

1、 Deep well pump product introduction: deep well pump is a water lifting machine with direct connection of motor and water pump. It is suitable for extracting groundwater from deep wells and water lifting projects such as rivers, reservoirs and canals. It is mainly used for farmland irrigation and water for people and livestock in plateau mountainous areas. It can also be used for water supply and drainage in cities, factories, railways, mines and construction sites. 2、 Features of deep well pump: 1. Motor and water pump are integrated, running in water, safe and reliable. 2. There are no special requirements for well pipe and lifting pipe (i.e. steel pipe well, ash pipe well, earth well, etc; Under the permission of pressure, steel pipe, rubber pipe and plastic pipe can be used as lifting pipe). 3. The installation, use and maintenance are convenient and simple, the floor area is small, and there is no need to build a pump house. 4. Simple structure and saving raw materials. Whether the service conditions of submersible pump are appropriate and properly managed is directly related to the service life. 3、 Meaning of deep well pump model: IV. service conditions of deep well pump: the deep well pump can operate continuously under the following conditions: 1. Three phase AC power supply with rated frequency of 50Hz and rated voltage of 380 ± 5% v.

2. The water inlet of the pump must be below 1m of the dynamic water level, but the diving depth shall not exceed 70m below the static water level. The water depth from the lower end of the motor to the bottom of the well shall be at least 1m.

Screw pump uses the rotation of screw to suck and discharge liquid. The intermediate screw is the driving screw, which is driven by the prime mover, and the screws on both sides are driven screws, which rotate in reverse with the driving screw. Shanghai Sunshine pump industry is the first enterprise to carry out R & D and production

3. Generally, the water temperature shall not be higher than 20 ℃

4. Water quality requirements:

(1) Sand content in water shall not be greater than 0.01% (weight ratio); (2) the pH value is in the range of 6.5 ~ 8.5; (3) chloride ion content shall not be greater than 400 mg / L. 5. The well shall be positive, the well wall shall be smooth, and there shall be no staggered well tubes.

The deep well pump unit consists of four parts: water pump, submersible motor (including cable), water pipe and control switch. The submersible pump is a single suction multistage vertical centrifugal pump: the submersible motor is a closed water filled wet, vertical three-phase cage asynchronous motor, and the motor and the water pump are directly connected through claw or single barrel coupling; Equipped with three core cables of different specifications; The starting equipment is air switches and self coupling pressure reducing starters with different capacity levels. The water delivery pipe is made of steel pipes with different diameters and connected with flanges. The high lift electric pump is controlled by gate valve.

A rubber bearing is installed in the guide shell of each stage of deep well pump; The impeller is fixed on the pump shaft with a conical sleeve; The guide housing is integrated with threads or bolts.

A check valve is installed on the upper part of the deep well pump to avoid unit damage caused by shutdown water sag.

The upper part of the submersible motor shaft is equipped with labyrinth sand preventer and two reverse assembled skeleton oil seals to prevent quicksand from entering the electric motor. 5. The submersible motor adopts water lubricated bearing, and the lower part is equipped with rubber pressure regulating film and pressure regulating spring to form a pressure regulating chamber to regulate the pressure change caused by temperature; The motor winding adopts polyethylene insulation, nylon sheath durable consumer goods, water and electricity} magnetic wire. The cable connection mode is according to the cable joint process. Remove the joint insulation, scrape the paint layer, connect them respectively, weld firmly, and wrap one layer of raw rubber. Then wrap 2 ~ 3 layers of waterproof adhesive tape, wrap 2 ~ 3 layers of waterproof adhesive tape on the outside or wrap a layer of rubber tape (bicycle inner belt) with water glue to prevent water seepage.

The motor is sealed with precision stop bolts, and the cable outlet is sealed with rubber gasket. 7. The upper end of the motor has a water injection hole, a vent hole and a drain hole at the lower part.